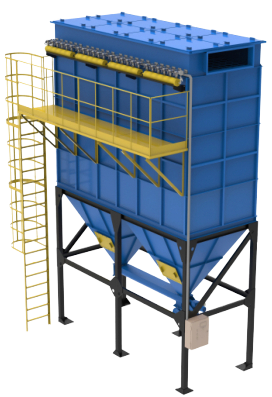

Mechmons Engineers is a Leading manufacturer of Bag Filter & Dust Collector in India. A Bag Filter, also known as a bag house, dust Collector or fabric filter, Cartridge Bag Filter. Our bag filters are highly efficient in removal of particulates or gas released from industrial processes.

Our bag filter is made with filters to withstand the ever-increasing heat and pressure of the working system. The material is chosen so carefully ensuring that it does not let the dirt particle escape from the system. The property of the material and its weaving ensures giving long life to the system and much-needed permeability.

A bag filter, also known as a fabric filter, is a type of air pollution control device that is commonly used in industrial settings to remove particulate matter from air streams. Bag filters are designed to capture particles of various sizes and types, including dust, smoke, and other airborne contaminants.

The basic design of a bag filter consists of a series of bags or sleeves made from a high-strength fabric material, such as polyester or fiberglass. The bags are arranged in a parallel configuration within a housing or casing, with one end of each bag open to the incoming air stream and the other end closed.

As the contaminated air flows through the bags, the particles are captured on the surface of the fabric material, while the clean air passes through and is discharged back into the environment. Over time, the particles accumulate on the surface of the bags, forming a cake that helps to increase the filtration efficiency.